Watchmaking

Due to the geographical location of DIXI Polytool, the watch-making sector constitutes a domain of excellence and competence of our business.

A wide range of standard tools, as well as a high reactivity for specialized tools are the basis of our success.

A team of competent and experienced application technicians are available to the clients for the optimisation of the existing production process or the development of new applications.

The main range of standard and specialized tools for the watch-making and jewellery sectors are as follows:

- Module cutters and targets

- Drills ≥ Ø 0.05mm

- End mills ≥ Ø 0.04mm

- Slitting saws

- Engraving tools

- Taps and gauges ≥ S0.30

- Micro whirling tools

- PCD and diamond tools

- Boring and chamfering tools

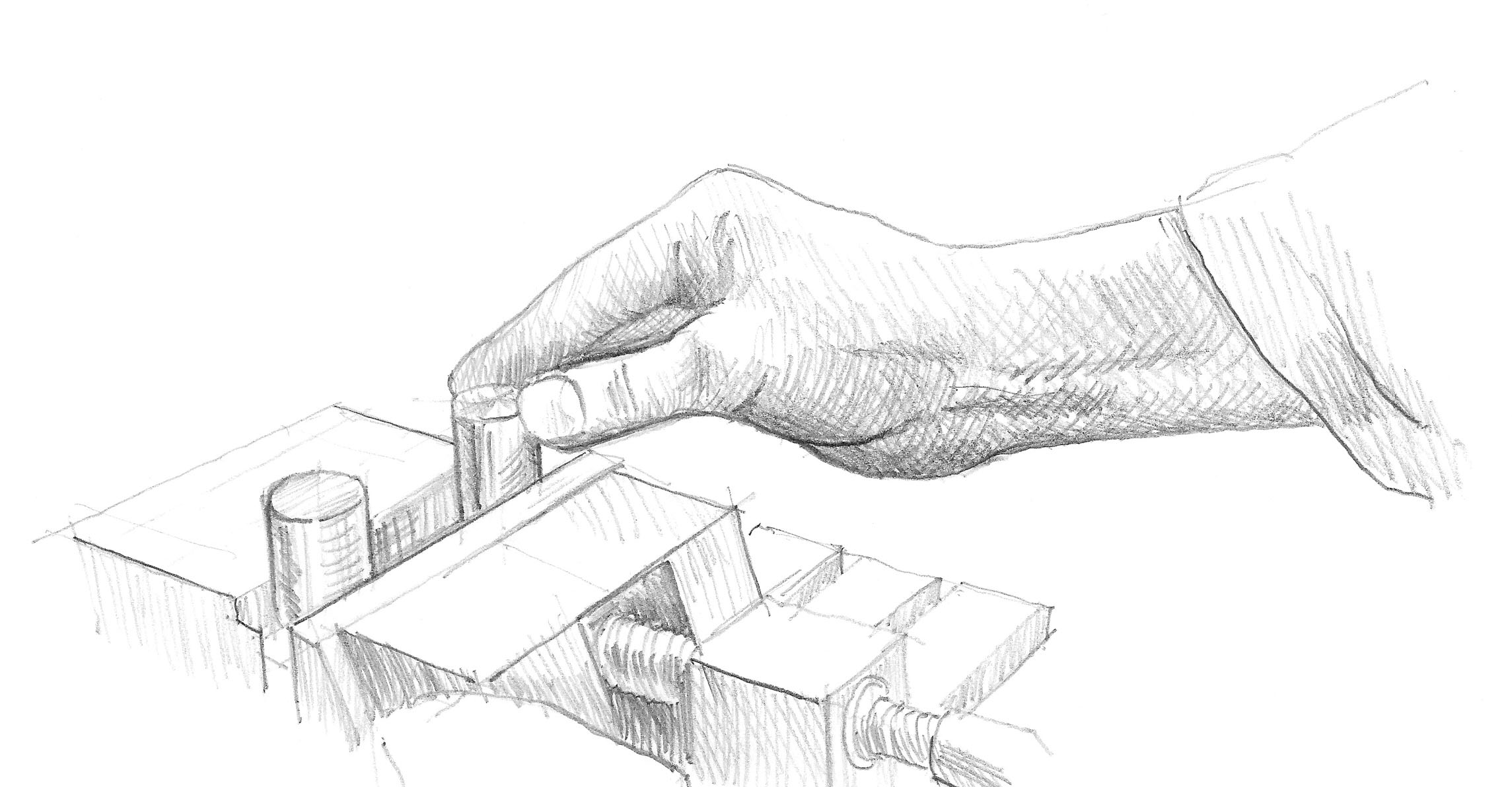

Turning screw cutting

Due to its geographical positioning in the Swiss Jura, DIXI Polytool has always been a privileged partner in the turning screw cutting sector. This is especially true in Switzerland, in the French Vallée de l’Arve and in the German Schwarzwald. In addition, our exceptional expertise contributes to the development of optimized solutions.

DIXI Polytool is not limited to offering standard tools; specialized tools are also very important in contributing to efficient solutions.

A team of competent and experienced application technicians are available to the clients for the optimisation of the existing production process or the development of new applications.

Our main offers for turning screw cutting are:

- Drills and micro drills in right and left hand versions

- Flat and stepped drills

- Slot drills and micro drills

- Slitting saw

- T-shape end mills

- Carbide reamers and micro reamers

- Boring tools

- Whirling tools

- PCD tools

Medical

Due to our competence in R&D, DIXI Polytool enjoyed strong growth in the medical sector in the last decade, in the machining of implants as well as ancillaries. The same applies to the dental industry.

The real challenges faced in these sectors are:

– Hard to machine materials, especially titanium, stainless, steel cobalt chrome or peek.

– Complex shapes to be machined.

– Maximal requirements in terms of tolerance and surface finish.

DIXI Polytool offers a wide range of standard tools dedicated to this sector but the reputation and strength of the company was built on its capacity to offer specialized and optimal solutions, thanks to the committed involvement of their technical engineers.

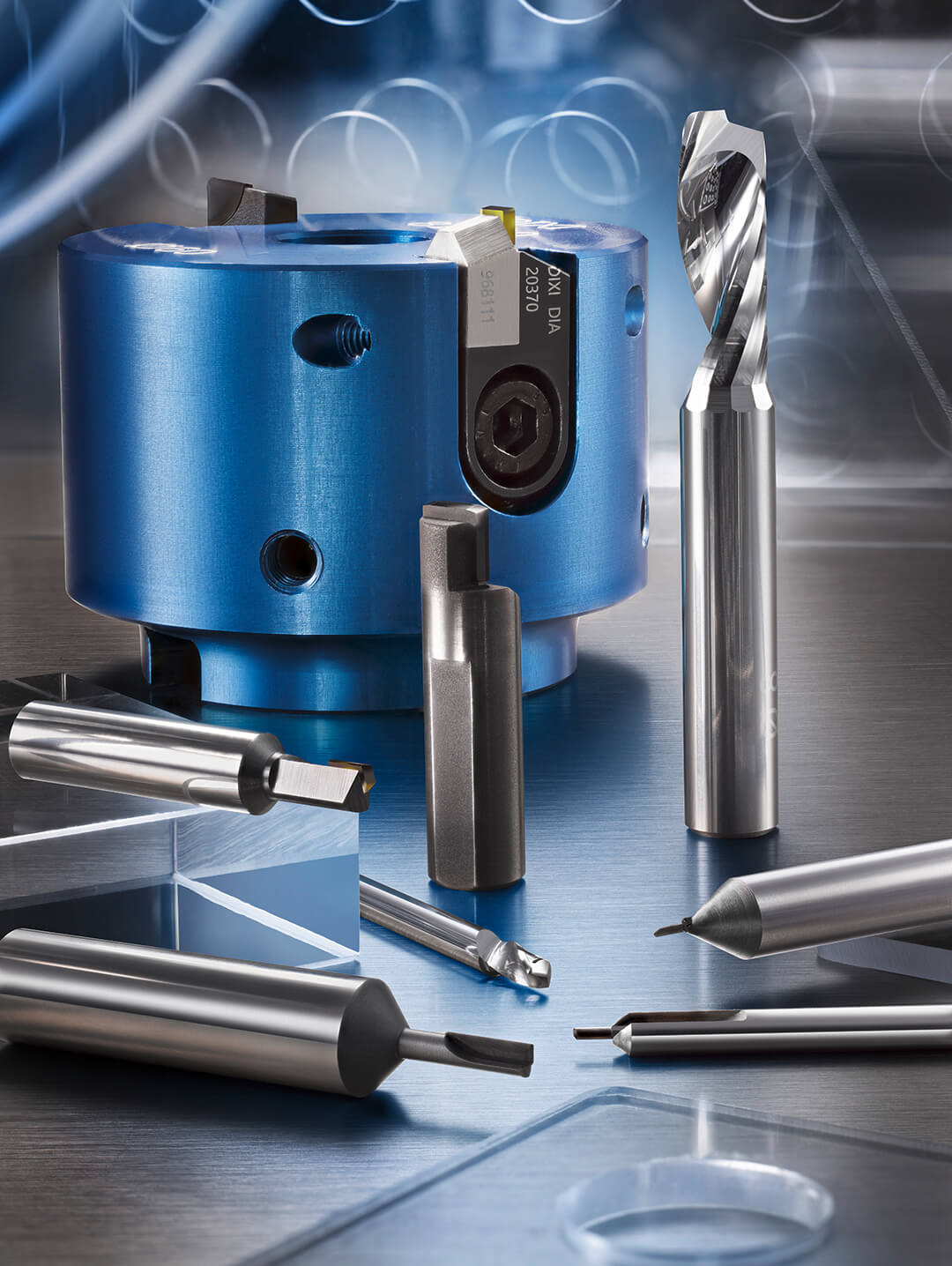

Automative/Aeronotics

Thanks to its efficient R&D department, DIXI Polytool has developed numerous solutions for these sectors and their subcontractors over the last decade.

The focus and efforts were primarily on:

- Carbide reamers and reamers with brazed inserts (Carbide, Cermet, PCD)

- Fixed or expandable heads (Carbide, Cermet, PCD)

- Expandable cutting rings (Carbide, Cermet, PCD)

- Whirling tools

- Sltitting saws

- Special end mills and drills

- PCD tools

General mechanics

The major asset of DIXI Polytool in the sector of general mechanics is the wide range of standard and specialized tools.

DIXI Polytool can provide the most performant tools for drilling, milling, threading, whirling, splitting or reaming.

A team of competent and experienced application technicians are available to the clients for the optimisation of the existing production process or the development of new applications.

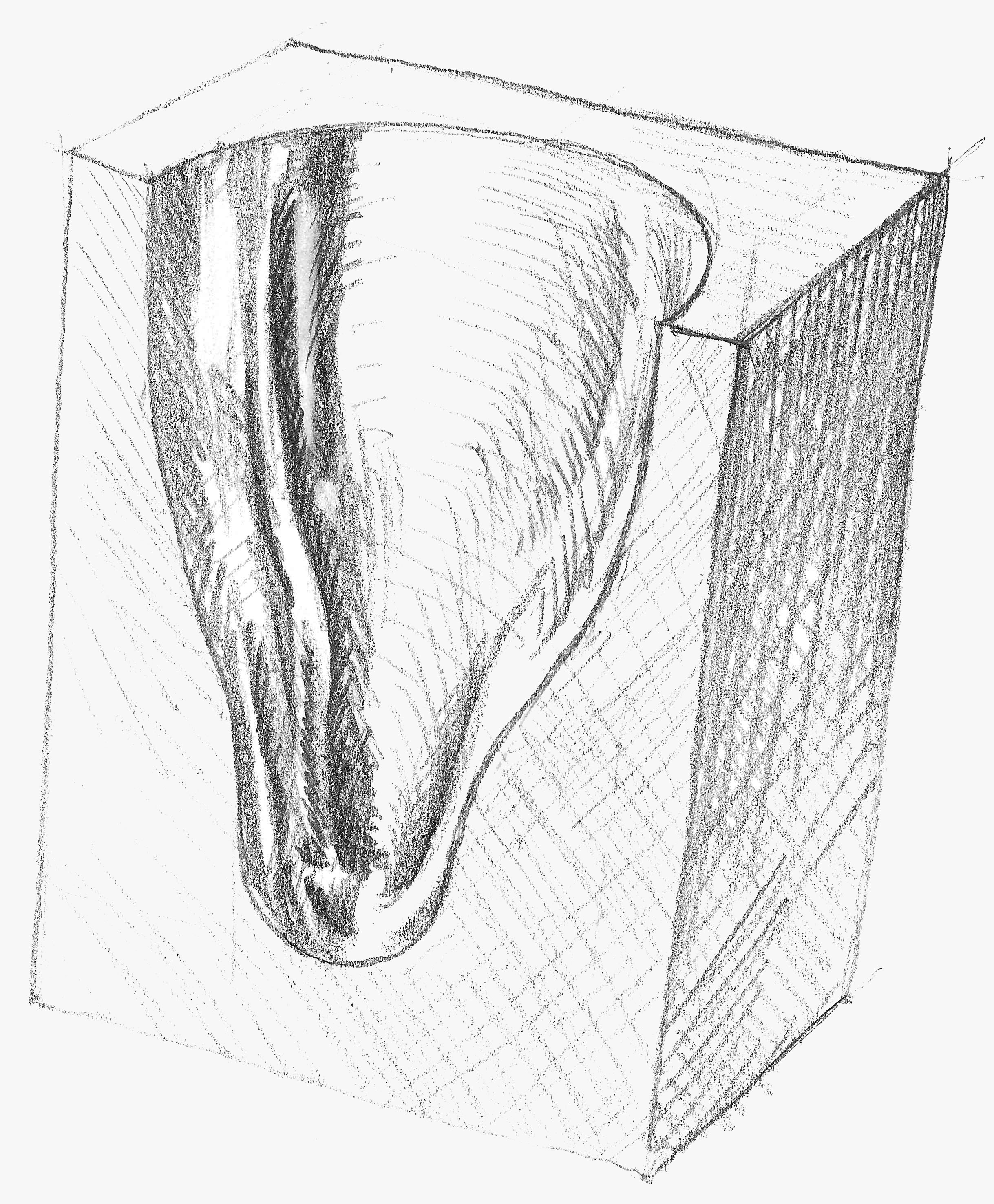

Mould and die

During the last few years, DIXI Polytool developed a wide range of tools dedicated to the mould-making sector.

A team of competent and experienced application technicians are available to the clients for the optimisation of the existing production process or the development of new applications.

The main range of standard and specialized tools for this sector are:

- Drills to machine hard steels up to 65HRC

- End mills and micro end mills for machining hard steel up to 65HRC

- Necked down end mills (up to 18xD1)

- Ultra-precise ball nose end mills or end mills with radic coated (TiALN, Diamond, Cutinox, DLC, DAC, DICUT) or non-coated

- Engraving tools

- PCD tools

Electronics or Micromechanics

Being a European Benchmark in micro tools, DIXI Polytool offers a very wide range of solutions for those sectors, in standard, as well as in specialized tools.

At the standard level, the tools offered are available from Ø 0.04mm and from Ø 0.02mm for specialized tools.

A team of competent and experienced application technicians are available to the clients for the optimisation of the existing production process or the development of new applications.

Wear Parts

DIXI Polytool S.A. is not only a specialist in carbide tools but also in carbide wears parts.

DIXI Polytool manufactures probes, punches, gauges, touches or wear parts based on drawings provided by the customer.

DIXI Polytool’s knowledge is very important in this high-precision field and several prestigious manufacturers of measurement and metrology machines have placed confidence in us for decades.

Plastic

CUTTING TOOLS DEDICATED TO THE MACHINING OF PLASTIC, COMPOSITES AND ALUMININUM